More actions

| Samsung Galaxy A03s CPU Swap Step by Step Guide | |

|---|---|

| Type | Method |

| Device(s) | Galaxy A03s |

| Difficulty | ◉◉◉◉ Specialist |

Problem description

If you have a Samsung A03s that does not boot up, and all other efforts to fix the existing board has failed, then you can follow this guide on how to swap the paired chips onto another working board for the purposes of recovering the data that's trapped inside the chips.

🚨 Please Note 🚨

This process is super risky & requires tons of practice & skill to successfully do it.

If you damage the CPU or the UFS (Storage) chip, then it's game over. The data is gone forever.

So do not try this if you have no experience with CPU Swaps.

Absolutely DO NOT try this if you have no microsoldering experience.

I would recommend you practice on donor motherboards & once you can do it successfully 3 in a row, then you should have enough experience to do this on a live customer's board.

Recommended Tools

Hot Air Station: Atten ST-862D with 13mm Bent Nozzle

Soldering Iron: Aixun T420D with T210 Handle & JBC C210018 Knife Tip

Symptoms

- No Power

- Does not boot up

- No signs of life

- Board is cracked

- Board is water damaged beyond repair

Solution

Repair Steps

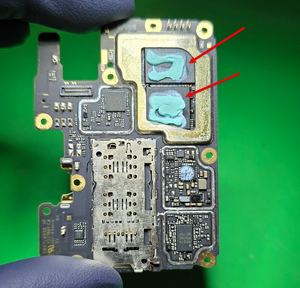

First, you need to locate the CPU and UFS.

- CPU holds the encryption keys

- UFS has the data, but it's encrypted

Both chips MUST be fully working & not damaged/cracked.

These chips talk to each other & during bootup, they exchange the keys so the phone can decrypt the data after the pin code is entered. Without the pin code, data cannot be decrypted & accessed.

Here's a picture of where these chips are:

Typically, these are next to each other & very large chips. They also tend to have thermal paste or thermal pads. Sometimes they have shields completely covering them.

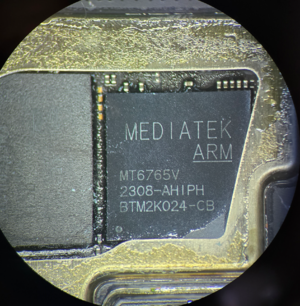

On this model, the CPU is labeled as MediaTek. So we can assume the other chip is the UFS.

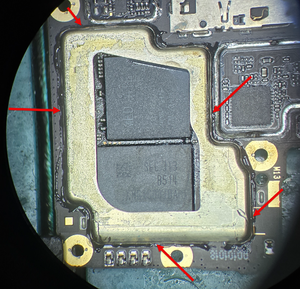

Now we must remove the shield around it to access the chips. I would recommend adding 138C Ultra Low Melt solder to the solder joints where the shield is attached to the board. Make sure to add plenty of flux & use a knife tip style iron

This will make removing the shield much easier

Using high temps, like 400C/60 air, heat around the perimeter

Use a hook tool or tweezers to grab onto the shield & pull it up, until it detaches, like this:

And now you have clear access to the 2 chips you need.

.