More actions

This page provides information to support DIY repair of ClipperCreek HCS series EV charging stations, which include the popular HCS-40 and HCS-60 models. ClipperCreek has famously awesome customer support, including hardware swap if the unit is still under warranty. If out of warranty, well here you go.

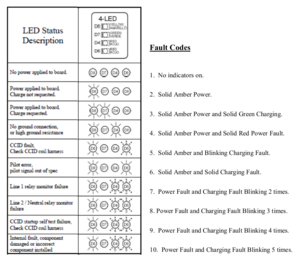

Clipper Creek HCS user manual (see page 16 for basic LED codes table)

More advanced LED codes table from CC's "HCS Troubleshooting Guide". Note that the number of blinks of the two bottom red LEDs is important. If two blinks, then the line 1 side of the contactor is failing; if three blinks, then line 2.

Relay / contactor information

Two of the failure modes involve the contactor. This is a Hongfa XMC0-402.IBBD , which is a 40-Amp, 2-pole contactor; see Hongfa's website for more on the XMC0 series. The Hongfa contactors catalog (PDF) includes XMC0 part number details on page 5/22, and cross references to other companies on page 2/22 (e.g. Tyco, Siemens). Other HCS-series units may have different make and model of contactors in them, but they should be drop-in replacements / compatible.

Background / failure modes

Brain dump from someone experienced with failure modes on these units:

- Corrosion at a terminal causing over heating of the wire inside the factory sealed box

- The one circuit board having a failure

- High ground leakage

- microswitch in the handle getting water in it and freezing, immobilizing the microswitch

- Pin contacts in the handle just wearing out from cycling-- or arcing on pullout, not supposed to work like that...

A common problem with Level 2 EVSEs is that the contactor welds itself closed. Typically not an issue with ClipperCreek though. OpenEVSE chargers like to do this later in life. After taking it apart and filing down the welds on the contact faces, you start just banging your fist on it real hard a couple times. Then power cycling it. That fist induced vibration was usually enough to break those welds, power cycle to clear the error, and get it working again for another month. Before it welded itself again. (will move this to OpenEVSE page later)

More product photos