More actions

| IPhone XS Max No Touch | |

|---|---|

| Device | IPhone XS Max |

| Affects part(s) | Motherboard |

| Needs equipment | Soldering Iron, Hot-Air Station, Microscope |

| Difficulty | ◉◉◉◌ Hard |

| Type | Soldering |

This article is a stub. You can help Repair Wiki grow by expanding it

Problem description

The device turns on but touch does not work

Symptoms

- Touch doesnt work.

Solution

The no touch problem can be caused by a display or a motherboard problem.

Diagnostic Steps

The first step is to always rule out faulty parts. Start by testing a new display.

If a new display doesnt not solve the issue inspect the Touch FPC for any physical damage or liquid damage.

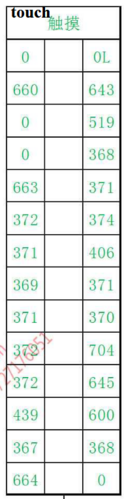

Take diode readings of the Touch FPC and compare them with the image on the side.

If everything is ok the next step is to check if the main touch voltages are present.

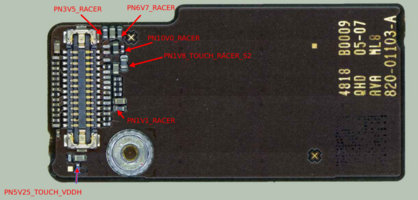

These voltages can be measured here, keep in mind that these voltages may only show up with the device powered on and a display connected.

PN6V7_RACER

PN3V5_RACER

PN10V0_RACER

PN1V8_TOUCH_RACER_S2

PN1V1_RACER

PN5V25_TOUCH_VDDH

If these voltages are present/or missing the next thing to do is split the boards, the most common issue is to have a crack on a solder joint between the interposer and the top board or a ripped pad.

The first thing you should do after splitting the boards is to check for any ripped pads, if you have any you need to check with a program like ZXW and see where that line goes.

Test with a tool similar to iSocket and turn on the phone and see if Touch works, if it is all you have to do is to reball the motherboard.

Repair Steps

If by replacing by trying a new display the touch fault is solved all you have to do its to replace the display.

If there is a any physical damage to the FPC the solution is to replace it. The best method is to use a hot air station to desolder the old FPC, clean the old solder from the motherboard, apply new solder, align the new FPC, and use the hot air station to solder it. (Be careful not to use excessive heat, as it may melt the FPC).

When taking diode readings of the FPC, if you measure a line that should read, for example, 0.500V but get 0.100V or 0.000V, it indicates a short on that line. The best way to trace the short is to inject voltage into the line with a DCPS and use a thermal camera to identify which component heats up.

If you measure a line that should read 0.500V but get OL (Open Line), it indicates a disconnection in the circuit. To trace the issue, consult the board view to follow the line’s path.

Final Testing

After assembling the phone, ensure every function is working as expected, not just the touch circuit.