| CRT General Repairs | |

|---|---|

| Type | Troubleshooting/Diagnostics |

| Device(s) | CRT Displays |

| Difficulty | ◉◉◉◌ Hard |

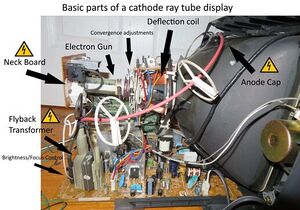

CRT (cathode ray tube) are found on older televisions, monitors, and other equipment.

Safety Warning:

CRT displays contain extremely high voltage (up to 30,000v!) and the acts as a capacitor which can store a lethal charge for weeks after the display has been unplugged. The tube MUST be discharged properly before performing any kind of internal repairs.

Here is a good guide to refer to for discharging CRTs: https://www.youtube.com/watch?v=1CVXzlkOjGg

CRTs also contain mains voltage so general electrical safety precautions should be taken when working on them.

Service Manuals:

Due to the facts that most CRTs come from a time when repair was more common and companies didn't claim it was a security risk to have someone replace a failed capacitor, complete service manuals that included full schematics were often given out to independent repair shops, in the cases of older televisions they may have even been included with the television. Many of these manuals and schematics are now available online, simply look up the model of your TV/monitor and look for a service manual.

Descriptions and service manuals for Commodore monitors can be found here: Commodore monitors

Repairs

| Symptom/Issue | Fix |

|---|---|

| General geometry issues, one side of screen is too disproportionally sized or is generally not scanning properly | Although a wide variety of things can cause such issues, one of the most common failures and causes of all sorts of issues in CRTs is capacitor failure. Low quality or aging electrolytic capacitors are often to blame for issues with CRT displays. Here are some general steps for troubleshooting capacitors:

|

| -Crackling, smoke smell, electrical spark sound that causes an temporary screen blackout.

-High voltage is present but screen is showing no sign of life. |

Although this can be an issue with the tube itself, at times these issues can sometimes be caused by issues with the neck board or flyback circuit, sometimes even just dust.

|

| Magnet damage, screen is badly distorted in colour and/or geometry. | "Magnet damage" in this case refers to when the internal parts of the tube have been affected by a magnet being brought near then which messes up a bunch of things and may make the display seem unusable, however it can sometimes be fixed (depending on severity.) The display needs to be degaussed there are 2 main ways to do this.

|

| Damaged or failed tube (glass not cracked or broken) | In many cases a damaged or failed tube is death knell for a CRT, the tube is the most expensive single part of the display and now that they are no longer in production finding a specific one is harder and more expensive then before. Years ago a damaged tube could be repaired at a component level by carefully cutting open the tube neck then literally rebuilding the electron gun, however shops that used to do this have all closed. The museum of early televisions has CRT rebuild equipment and is looking to one day offer it as a service to consumers. So if your tube has failed and you are dead set on keeping the display alive it may be worth holding out for that service to be available. |

| Damaged tube (glass cracked or broken) | At this point the only way to fix the display is to replace the tube; if you can find a tube for your display for a good price then replacing is fairly straightforward and a service manual can provide additions details. |

https://www.earlytelevision.org/crt_rebuilding_at_museum.html